|

Home | About Us | Contact Us | Product List | Service List | Related Links |

|

3064 Kenneth Street Santa Clara, CA 95054 |

|

To contact us: |

|

Phone: 408-855-8686 Email: info@agsplasma.com |

|

AGS Plasma Systems, Inc. |

|

Home |

|

AGS Plasma Systems, Inc. is the preeminent manufacturer of affordable vacuum plasma systems used for etching and deposition of patterns needed in the microelectronics, MEMS, solar, optoelectronics, and nanotechnology industries. The company was formed in 1991 to assist people with their plasma system's parts and service needs. We sell and service plasma systems and have designed and installed a variety of product enhancements. We also supply a Windows/PC process tool controller to add the ease and flexibility of GUI automation to your existing vacuum systems. We offer a complete line of vacuum systems for all your dry processing needs Now Celebrating Our 32nd year!

|

|

Plasma System Specialists PLASMA • ETCH • PECVD • HDP |

|

Home |

|

Company Info |

|

Contact Us |

|

Products

|

|

Support |

|

Related Links |

|

AGS Plasma Headline News: Santa Clara, CA — AGS Plasma Systems released the following late breaking news today. |

|

Another OEM Module Customer |

|

In another story, AGS Plasma revealed that they have signed with yet another major semiconductor tool supplier to provide OEM versions of their MPS‑X00‑RIE and PECVD modules. President, Allen Guastavino said, “This is our fourth OEM customer for this part of our strategic business model of delivering turn-key plasma module solutions at very competitive prices to OEM’s to rebrand as their own. Buying our mature IP facilitates rapid deployment at minimal investment and risk for any OEM that desires to add plasma processing to their portfolio.” |

|

AGS announce new bench top research systems |

|

At Semicon West 2012, a new table top reactor, the TT-150-RIE/CVD™, was unveiled by AGS Plasma Systems. The economical new system for Reactive Ion Etch and Plasma Enhanced CVD applications is perfect for the needs of researchers throughout the world. The modular TT-150 is well suited for 2-6" semiconductor, MEMS, TFT, and PV work. “We have designed a really solid bench top reactor based on our MPS-150 platform,” said Russ Coppes, Senior Engineer, AGS Plasma. The system is immediately available with a number of enhancement options. |

|

Prestigious Russian Academy of Sciences awards ICP systems order AGS Plasma Systems has been award an order for their MPS-150-ICP/RIE™ platform for ICP-Reactive Ion Etch applications by the prestigious Russian Academy of Sciences. The modular MPS-150 is well suited to meet the unique demands of 2-6" compound semiconductor research. “It is thrilling to be working with the caliber of scientists at the RAS and we are very proud,” said Allen Guastavino, CEO, AGS Plasma. The system was scheduled to be delivered in mid 2011.

AGSP Receives New Orders for ALD Pre-Clean Modules As the semiconductor capital equipment spending boom surges in 2010, AGS Plasma Systems has received several orders for their MPS-200™ platform for 200 mm Reactive Ion Etch, or RIE, pre-clean applications on an ALD cluster tool. The modular MPS-X00 is an excellent choice for data storage component manufacturing. “These are our first plasma etch systems to be used on a major capital equipment companies atomic layer deposition products. We are excited to see growth for AGSP into this new area,” said Allen Guastavino, CEO, AGS Plasma. |

|

AGSP Books Orders During Downturn

In another story, AGS Plasma revealed that they have signed with yet another major semiconductor tool supplier to provide OEM versions of their MPS‑X00‑RIE and PECVD modules. President, Allen Guastavino said, “This is our fourth OEM customer for this part of our strategic business model of delivering turn-key plasma module solutions at very competitive prices to OEM’s to rebrand as their own. Buying our mature IP facilitates rapid deployment at minimal investment and risk for any OEM that desires to add plasma processing to their portfolio.” |

|

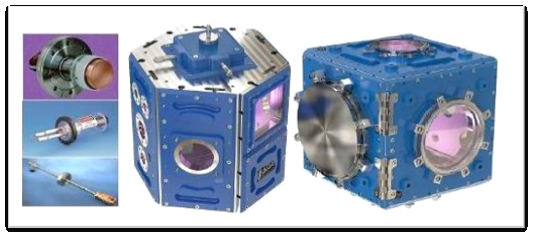

Figure 1- MPS-150L-ICP Metal Etch System |

|

Carbon Nanotechnology Order AGS Plasma announced that it has received an order for an advanced MPS-150-ICP plasma deposition tool for use in carbon nanotechnology research. A Biotech firm has been working with AGSP for the last year to develop the new technology required to combine plasma and chemical vapor deposition at very high temperatures necessary for the deposition of nanotubes, nanosheets, and graphene. AGSP president and CEO, Allen Guastavino, said, “This is part of our five year plan to be a leader in delivering solutions to the nanotechnology industry. We are excited to be in on the ground floor of commercializing products in this new and growing market.”

|

|

AGS Plasma Systems is very excited to be awarded an order for their Penta PVD™ IBSD for Isotope Deposition to Oak Ridge National Laboratory, the largest US Department of Energy science and energy laboratory. The order has shipped and we are receiving rave reviews! AGS Plasma Systems was mentioned as part of a recent ORNL white paper "Ion Beam Sputter Deposition of Rare Materials for Thin Films". "We have been working for over 3 years, and look forward to many more orders and service opportunities” said Allen Guastavino, CEO, AGS Plasma. Jacque Greer, Business Development Manager has been working with partners to help develop our Materials Research and Biotechnology application processes in this new and evolving Research & Development. |

|

Penta PVD™ IBSD New Order with Oak Ridge National Laboratory |

|

Now offering the Ideal Vacuum Cube Range and introducing the

Hex & Penta-PVD series of modular deposition systems! |

|

Please visit us at NCCAVS 2023!!! Fremont Marriott Silicon Valley 46100 Landing Pkwy |